Red Dye Penetration Test — The Invisible Guardian of Product Quality through Precise Inspection

Red Dye Penetration Test

The Invisible Guardian of Product Quality through Precise Inspection

In the high-precision manufacturing industry, product quality and reliability are directly linked to a company's competitiveness and brand image. This is especially true for critical components that require extreme durability and safety, such as those used in aerospace, automotive, medical, and electronic devices. Even the smallest defect can result in product failure or safety incidents. Therefore, precise quality inspection for these products is essential.

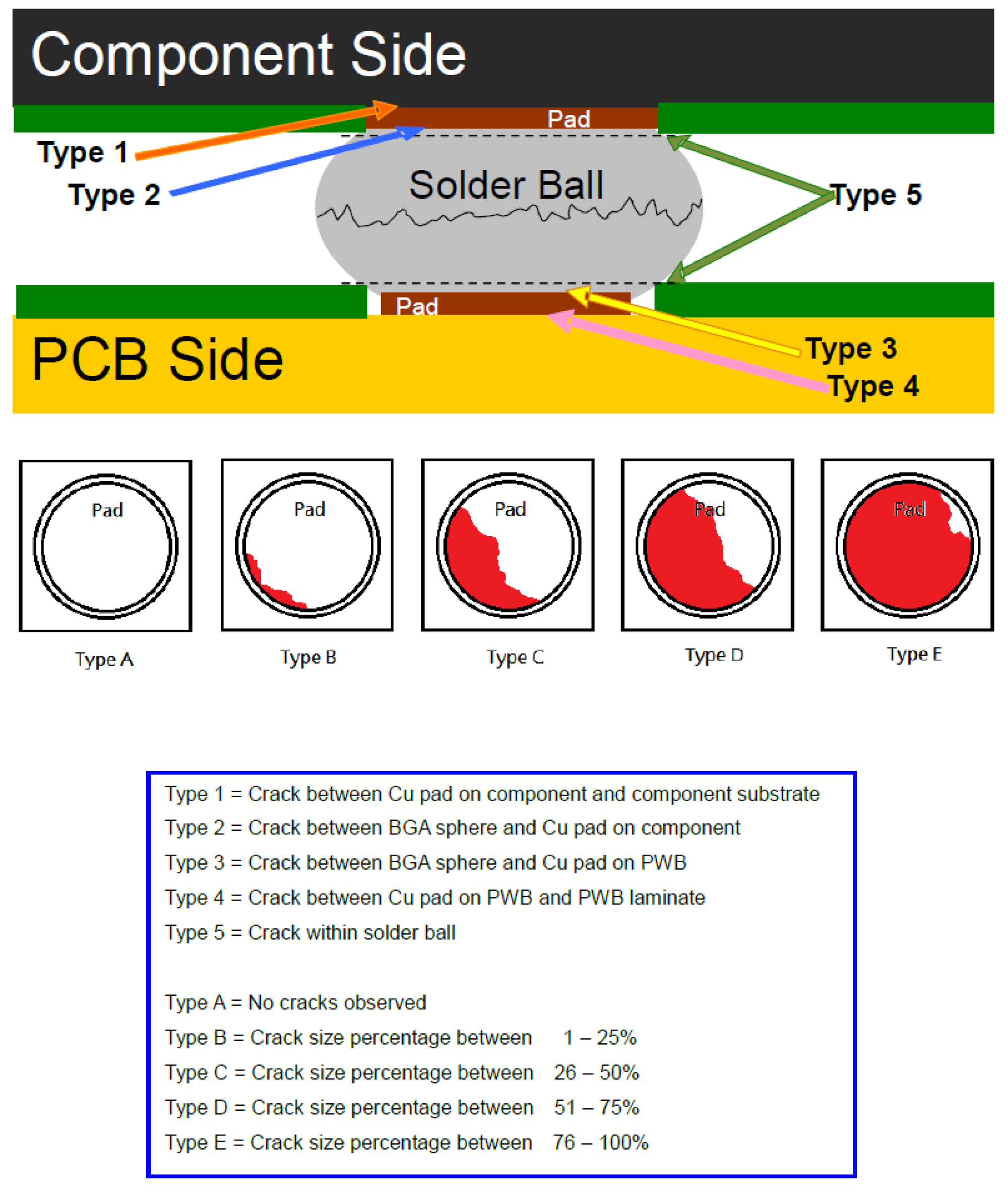

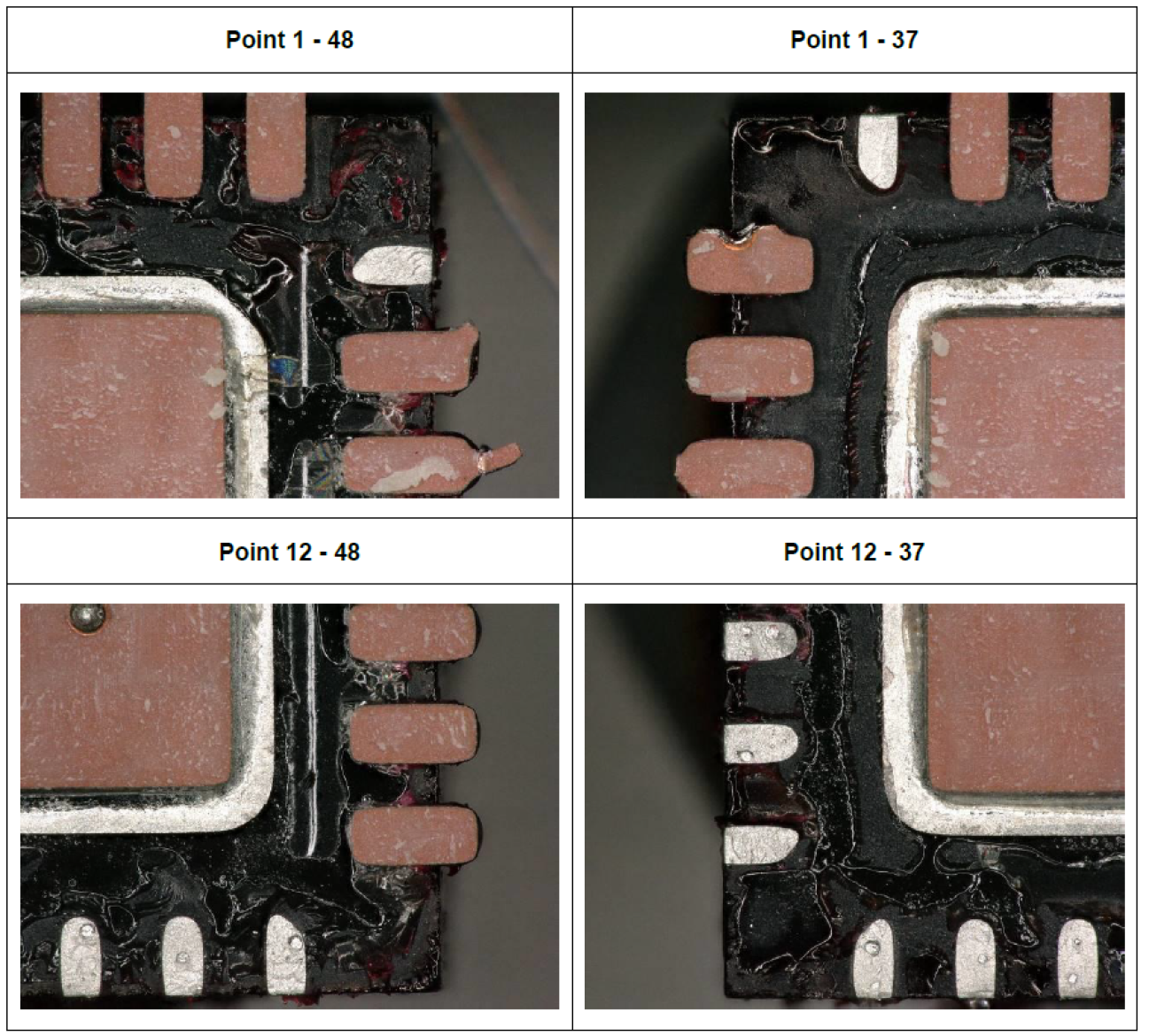

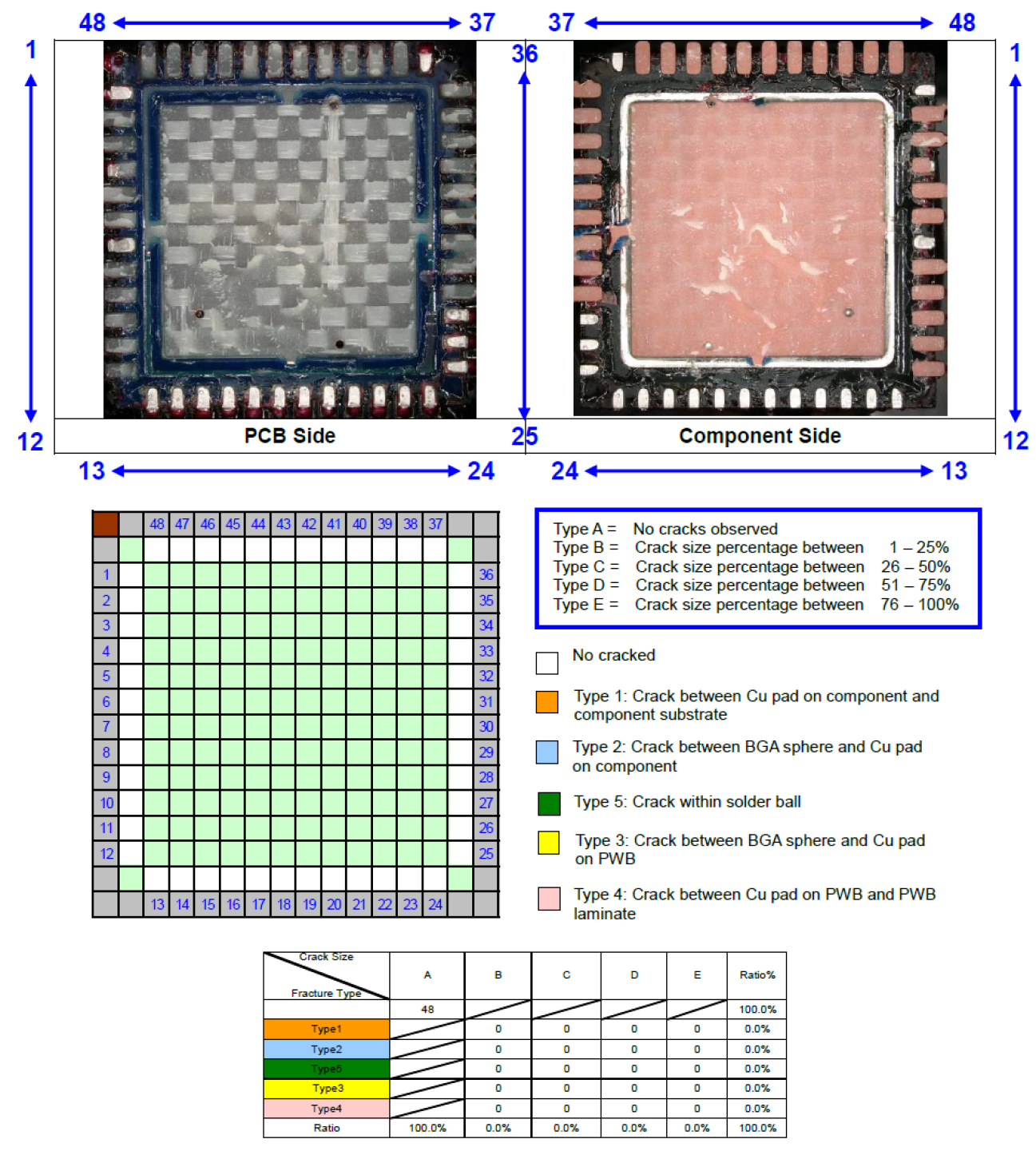

The red dye penetration test, an effective surface defect detection technique, has been widely adopted across various manufacturing fields. This technique involves applying red dye to the soldering surface of the product. The soldering surface of the product is then inspected using a high-magnification microscope. By comparing the results to standard images of red ink infiltration (Figure 1), the quality of the product's solder joints can be confirmed. This process helps companies identify potential risks in product design and manufacturing processes early on, preventing defective products from entering the market.

Working Principle of the Red Dye Penetration Test

Enhancing Product Reliability and Reducing Risk

Want to learn more?